Now for the first gluing process on the Oz Goose Sailboat. This video demonstrates how quickly the hull goes together because all the groundwork was done first with the dry assembly.

Don’t forget to take care measuring and mixing the epoxy.

Don’t overtighten the Temporary screws

Epoxy does not need to be screwed together tightly. The surfaces just need to contact gently. There is no need to crush the wood together.

Just screw until the surfaces just touch.

Note how the battery drill is being gently by squeezing the trigger gently.

Because you are simply reassembling the parts that have been together this doesn’t take very long.

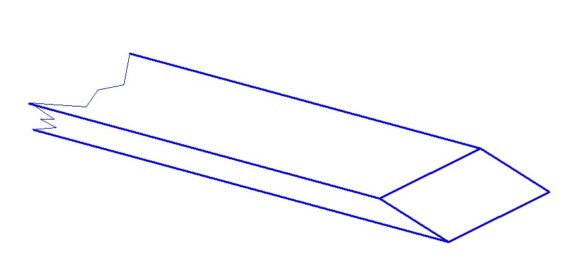

Make sure the hull is not twisted!

Once the gluing and screwing is finished check the hull is not twisted as any twist will be glued in at this point.

Sight the top edge of the bow transom compared to the top edge of the stern transom. Move the chairs or blocks until they are parallel.

Tidy up the assembled hull by removing excess glue and filling any gaps in the corners

After completing the assembly tidy up excess epoxy. I recommend sharpening a tongue depressor or piece of ply to have an edge like a chisel. It cleans up very neatly. Put sandpaper on a flat surface and sand the bevel (the sloped surface) then gently sad the tip from the other side to get a nice sharp edge.

Any messy epoxy glue takes a long time to sand when it is hard – so work clean.

Excess glue can be used inside the tank area to fill any gaps in the corners. Don’t do any filling where it will be able to be seen in the cockpit area or if you want to make it very clean and neat.

Double check for hull twist

Next Day remove the temporary screws

First of all, check the epoxy is hard by rapping it with the ends of your fingernails. If it is hard enough it will feel like rock and your fingernails will bounce off. If it still needs to cure it will feel rubbery.

If it feels hard remove the screws. Don’t worry about filling the screw holes yet. We have a special method and will do them all at once.

If the screws are not removed when the epoxy is hard some of them will become glued in and the heads may break off.